PVC Boxes Gift Packaging for Food Clear Plastic 0.2-0.5mm

Send Inquiry- Material Structure:

-

PVC/PP/PET, Eco-friendly Plastic Package

- Printing Handling:

-

Embossing, UV Coating, Varnishing, Glossy Lamination, Stamping, Matt Lamination

- Feature:

-

Handmade, Portable,Customized,small MOQ

Size:

Custom Clear Plastic PVC Gift Packaging Box Macaron Food Packaging PVC Box Packaging Printing

- The custom plastic PVC boxes with printing are transparent folding boxes. Cylinders, top cover and base boxes, hand bags, hanging tags, and other related plastic products made of PVC/PET/PP/PS materials.

- The PVC boxes can achieve printing effects such as UV offset printing, silk screen printing, gold/silver stamping, frosted effect, etc.

- Plastic or PVC boxes packaging with custom design have the characteristics of increasing user experience. Permanently durable packaging, moisture-proof, waterproof, high toughness, strong transportation safety performance, and improving product grade.

- PVC Boxed packaging containers PVC gift packaging boxes are made of plastic. It have many characteristics such as low density, light weight, and easy processing.

- The appearance can be transparent or opaque. Recyclable PET/PP box clear transparent plastic packaging box is widely used in the food packaging industry. For example,the picture shown is clear plastic macaroon food packaging box.

Specifications:

Custom Clear Plastic PVC Gift Packaging Box Macaron Food Packaging PVC Boxes Packaging Printing

|

Material

|

PET/PVC/PP

|

||

|

Color

|

Any color in Pantone or CMYK; We have UV printing machine

|

||

|

Printing

|

CMYK, UV printing, Silk-screen printing, Hot stamping, Glossy lamination, Matt lamination, Vanishing

|

||

|

HS Code

|

3923100090

|

||

|

Price

|

Lower factory price. From printing to packing, we have complete production line.

|

||

|

Production Time

|

1-2 days for sample printing, 10 days for bulk printing

|

||

|

Certification

|

SGS, ISO9001, Intertek

|

||

Specifications of Custom Printed PVC Boxes

-

Material: Premium food-grade PVC (Polyvinyl Chloride), available in 0.2mm to 0.5mm thickness.

-

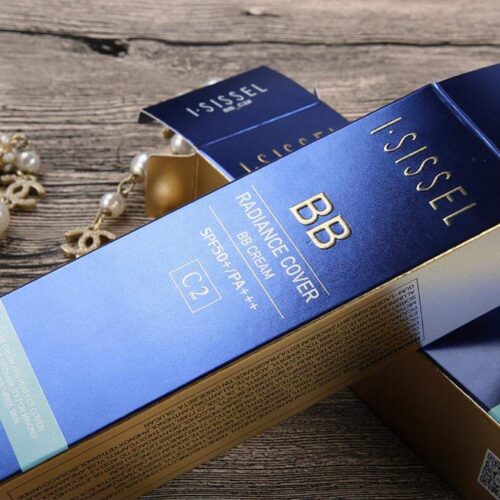

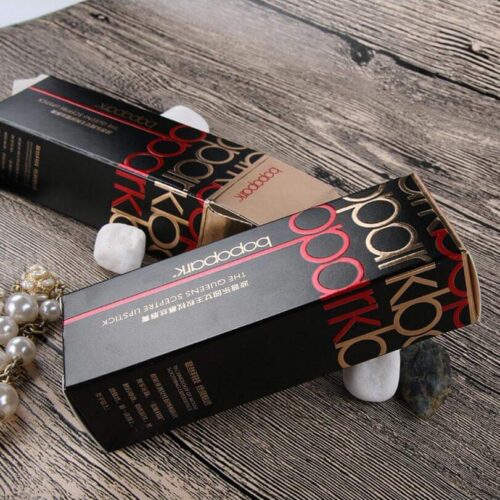

Printing: Full-color CMYK or PMS silk screen/offset printing with matte, glossy, or frosted effects.

-

Surface Finish: Optional foil stamping (gold/silver), spot UV, debossing/embossing, or holographic overlay.

-

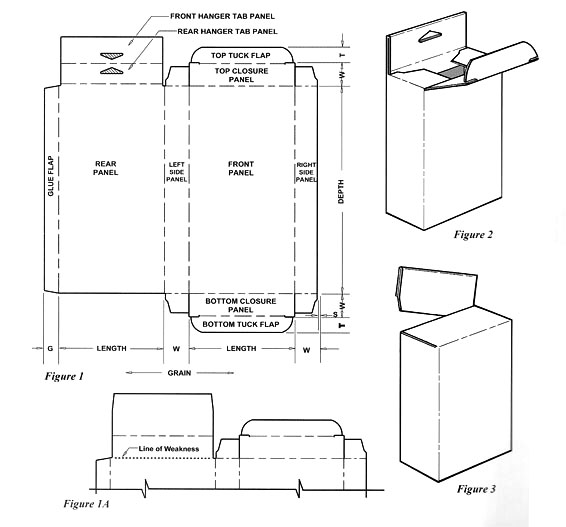

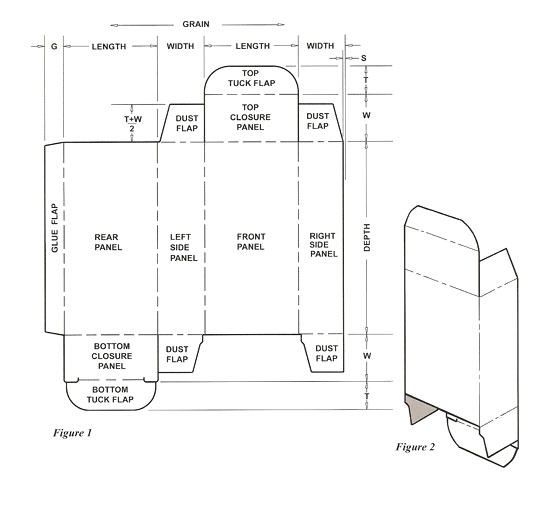

Structure: Foldable and die-cut designs with auto-lock bottom, tuck-in top, or custom closures.

-

Transparency: High clarity, semi-transparent, or fully opaque finishes available.

-

Size Range: Fully customizable dimensions—ideal for cosmetics, electronics, gifts, and retail items.

-

Eco-Friendly Options: Recyclable PVC material or switchable to PET if required.

-

Strength: Heat-sealed edges and rigid body for optimal protection and presentation.

-

Packaging: Flat-pack delivery or pre-folded, based on client preference and shipping cost.

-

Add-ons: Handle holes, hang tabs, inner trays, and inserts for enhanced functionality.

Custom Clear Plastic PVC Gift Packaging Box Macaron Food Packaging PVC Box Packaging Printing

Why Choose CHINAPRINTINGGROUP for Custom PVC Boxes?

-

Rich Experience: Over 20 years in the packaging industry with a strong focus on clear and custom plastic packaging.

-

In-House Manufacturing: Full control over quality, cost, and production speed with zero outsourcing.

-

High-Quality Printing: Advanced UV, silk screen, and offset printing machines ensure premium print results.

-

Material Expertise: We offer a wide range of PVC grades, plus PET, PP alternatives based on your needs.

-

Design Support: Free dieline templates and artwork advice from expert designers.

-

Strict Quality Control: Multi-step quality inspection system from raw material to final packaging.

-

Competitive Pricing: Factory-direct prices with bulk discounts and packaging consultations.

-

Fast Turnaround: Rapid prototyping and production processes to meet urgent delivery timelines.

-

Eco-Conscious Options: Support for recyclable materials and environmentally friendly packaging goals.

-

Responsive Service: Bilingual customer support team ensuring smooth communication and fast assistance.

Price Structure for Custom Printed PVC Boxes

The cost of custom printed PVC boxes varies based on several factors, including material thickness, printing techniques, order quantity, and additional features. Here’s a breakdown to help you estimate expenses:

1. Material Thickness

-

0.2mm to 0.3mm: Suitable for lightweight items; more cost-effective.

-

0.4mm to 0.5mm: Provides sturdiness for heavier products; slightly higher cost.

2. Printing Techniques

-

Silk Screen Printing: Ideal for simple designs and solid colors.

-

Offset Printing: Best for complex, full-color images; higher setup costs but lower per-unit cost for large volumes.

-

Digital Printing: Suitable for small runs; no setup costs but higher per-unit price.

3. Order Quantity

-

1,000 units: Approximately $0.30–$0.60 per unit.

-

10,000 units: Approximately $0.20–$0.40 per unit.

-

50,000 units: Approximately $0.15–$0.30 per unit.

Note: Prices are indicative and can vary based on specific requirements and market conditions.

4. Additional Features

-

Foil Stamping: Adds $0.05–$0.10 per unit.

-

Embossing/Debossing: Adds $0.05–$0.15 per unit.

-

Spot UV Coating: Adds $0.03–$0.07 per unit.

-

Custom Inserts: Adds $0.10–$0.25 per unit.

🛍️ Application Scenarios for Custom Printed PVC Boxes

Custom printed PVC boxes are versatile and cater to various industries. Here are some common applications:

1. Retail Packaging

Ideal for showcasing products like electronics, cosmetics, and toys. The transparency allows customers to view the product without opening the package.

2. Food Packaging

Suitable for items like chocolates, candies, and baked goods. PVC boxes can be made food-safe and provide an attractive display.

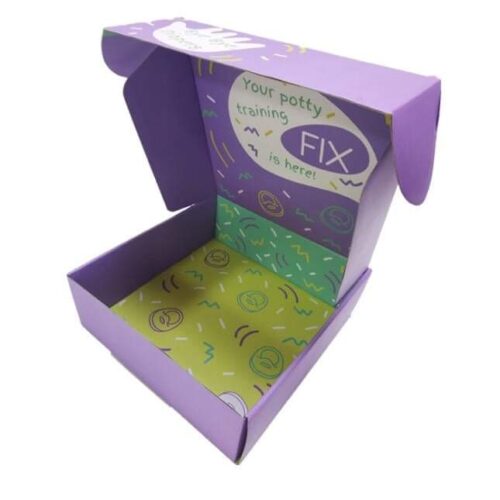

3. Gift Packaging

Enhances the presentation of gifts for occasions like weddings, birthdays, and corporate events. Custom printing adds a personalized touch.

4. Promotional Packaging

Used for marketing campaigns to create brand awareness. Unique designs and high-quality printing can make promotional items stand out.

5. Subscription Boxes

Provides a premium unboxing experience for monthly subscription services, especially in beauty and lifestyle sectors.

🎨 Design Requirements for Custom Printed PVC Boxes

To ensure the best outcome for your custom PVC boxes, consider the following design requirements:

1. Artwork Specifications

-

File Format: AI, PSD, or PDF with vector graphics.

-

Resolution: Minimum 300 DPI for images.

-

Color Mode: CMYK for accurate color reproduction.

-

Bleed: Include a 3mm bleed on all sides.

2. Structural Design

-

Dimensions: Provide exact measurements (length, width, height).

-

Closure Type: Decide between tuck-end, auto-lock bottom, or custom closures.

-

Window Cutouts: Specify if any transparent windows are needed.

3. Material Selection

-

Clarity: Choose between clear, frosted, or colored PVC.

-

Thickness: Select appropriate thickness based on product weight and durability requirements.

4. Finishing Options

-

Coatings: Glossy or matte finish to enhance appearance.

-

Special Effects: Foil stamping, embossing, or spot UV for premium look.

If you need assistance with design templates or have specific requirements, feel free to ask. We can provide dieline templates and further guidance to help you create the perfect custom printed PVC boxes for your product.

How to Make Your Custom PVC Boxes Stand Out?

Enhancing the appeal of your PVC boxes can significantly impact customer perception and brand recognition. Here are some strategies:

1. Innovative Structural Designs

-

Unique Shapes: Experiment with non-traditional shapes to capture attention.

-

Functional Features: Incorporate handles, magnetic closures, or compartments for added utility.

2. Premium Finishes

-

Surface Treatments: Utilize matte, glossy, or frosted finishes to match your brand aesthetic.

-

Special Effects: Apply foil stamping, embossing, or spot UV to highlight logos or designs.

3. High-Quality Printing

-

Vivid Colors: Use CMYK or Pantone color matching for brand consistency.

-

Clear Imagery: Ensure high-resolution images and graphics for a professional look.

4. Interactive Elements

-

Windows: Add transparent windows to showcase the product inside.

-

QR Codes: Include scannable codes linking to product information or promotions.

5. Eco-Friendly Messaging

-

Sustainability Indicators: Clearly label recyclable materials or eco-friendly practices.

-

Minimalist Design: Opt for designs that reduce material usage without compromising integrity.

📏 Maximum Size Capabilities for PVC Boxes

The size of custom PVC boxes can be tailored to your specific needs. While there isn’t a universal maximum size, considerations include:

-

Material Strength: Larger boxes may require thicker PVC to maintain structural integrity.

-

Manufacturing Constraints: Some manufacturers may have limitations based on equipment capabilities.

-

Shipping and Handling: Oversized boxes might incur higher shipping costs or require special handling.

It’s advisable to consult with your packaging supplier to determine feasible dimensions for your project.

🌿 Eco-Friendliness of PVC Boxes

PVC (Polyvinyl Chloride) has been a topic of environmental discussions. Here’s an overview:

♻️ Recyclability

-

Limited Recycling: PVC is recyclable, but not as widely accepted as materials like PET or HDPE.

-

Specialized Facilities: Recycling PVC often requires specialized facilities, which may not be readily available in all regions.

🌱 Sustainable Alternatives

-

rPET Boxes: Made from recycled PET, these boxes offer similar clarity and durability with improved recyclability.

-

Biodegradable Plastics: Materials like PLA (Polylactic Acid) provide compostable options, though they may have different performance characteristics.

✅ Recommendations

-

Material Selection: If sustainability is a priority, consider alternative materials that align with your environmental goals.

-

Consumer Communication: Clearly communicate the recyclability and disposal methods of your packaging to end-users.

If you need assistance in selecting the right materials or designing standout packaging, feel free to ask!

Custom printed PVC boxes are widely utilized across various industries due to their versatility, durability, and aesthetic appeal.

Applications of Custom Printed PVC Boxes

-

Retail Packaging: Ideal for showcasing products like electronics, cosmetics, and toys. The transparency allows customers to view the product without opening the package.

-

Food Packaging: Suitable for items like chocolates, candies, and baked goods. PVC boxes can be made food-safe and provide an attractive display.

-

Gift Packaging: Enhances the presentation of gifts for occasions like weddings, birthdays, and corporate events. Custom printing adds a personalized touch.

-

Promotional Packaging: Used for marketing campaigns to create brand awareness. Unique designs and high-quality printing can make promotional items stand out.

-

Subscription Boxes: Provides a premium unboxing experience for monthly subscription services, especially in beauty and lifestyle sectors.

🌟 Reasons for the Popularity of PVC Boxes

-

Transparency: Allows consumers to see the product inside, building trust and aiding in purchasing decisions.

-

Durability: PVC is resistant to moisture and damage, ensuring product protection during storage and transport.

-

Customizability: Supports various printing techniques and finishes, enabling brands to create unique and eye-catching designs.

-

Cost-Effectiveness: Offers a balance between quality and affordability, making it a preferred choice for many businesses.

-

Versatility: Suitable for a wide range of products and industries, from food to electronics.

These attributes make custom printed PVC boxes a popular packaging solution that combines functionality with aesthetic appeal.

Choosing PVC (polyvinyl chloride) boxes over traditional paper packaging offers several advantages, particularly for businesses aiming to enhance product presentation, durability, and functionality. Here’s a detailed comparison to help you understand why PVC boxes might be the preferable choice for your packaging needs:

📦 Advantages of PVC Boxes Over Paper Packaging Boxes

1. Enhanced Durability and Protection

PVC boxes are highly resistant to moisture, tearing, and physical damage, ensuring that products remain protected during transportation and storage. In contrast, paper packaging is more susceptible to environmental factors like humidity and can degrade more quickly, potentially compromising the product inside.

2. Superior Clarity and Product Visibility

The transparency of PVC allows consumers to view the product without opening the package, enhancing trust and appeal. This is particularly beneficial for items like cosmetics, electronics, and food products, where visual appeal influences purchasing decisions. Paper packaging typically lacks this feature unless combined with plastic windows, which can complicate recycling efforts.

3. Versatile Design and Customization

PVC can be easily molded into various shapes and sizes, accommodating unique product designs and branding requirements. It supports a range of printing techniques, including silk screen and offset printing, allowing for vibrant and detailed graphics. Paper packaging, while customizable, may have limitations in achieving certain structural designs and finishes.

4. Lightweight and Space-Efficient

PVC’s lightweight nature reduces shipping costs and makes handling more convenient. Additionally, PVC boxes can be designed to be collapsible, saving storage space when not in use. Paper packaging, depending on its thickness and design, may not offer the same level of space efficiency.

5. Cost-Effectiveness for Long-Term Use

While the initial cost of PVC packaging might be higher than paper, its durability and reusability can lead to cost savings over time, especially for products that require long shelf lives or are subject to frequent handling. Paper packaging may need to be replaced more often, potentially increasing long-term expenses.

🌿 Environmental Considerations

- It’s important to note that PVC is a type of plastic, and its environmental impact has been a topic of discussion.

- While PVC is recyclable, the recycling process can be more complex compared to paper.

- However, advancements in recycling technologies and the development of eco-friendly PVC alternatives are addressing these concerns.

- On the other hand, paper packaging is biodegradable and often sourced from renewable materials.

- Yet, its production can be resource-intensive, involving significant water and energy consumption.

- Additionally, paper packaging may not offer the same level of protection, potentially leading to increased product waste.

- Opting for PVC boxes over paper packaging can provide enhanced durability, superior product visibility, and versatile design options,

- Making them an excellent choice for businesses aiming to elevate their product presentation and protect their goods effectively.

- While considering environmental impacts is crucial.

- The benefits of PVC packaging in terms of functionality and longevity often outweigh the drawbacks, especially when combined with responsible recycling practices.

PVC boxes are highly suitable for toy packaging, offering a blend of functionality and visual appeal that can enhance your product’s market presence.

Advantages of PVC Boxes for Toy Packaging

1. Enhanced Product Visibility

PVC’s clarity allows consumers to view the toy without opening the package, building trust and aiding in purchasing decisions. This transparency is particularly beneficial for showcasing detailed or colorful toys.

2. Durability and Protection

PVC boxes are resistant to moisture, tearing, and physical damage, ensuring that toys remain protected during transportation and storage. This durability is crucial for maintaining product integrity, especially for delicate or collectible items.

3. Customizable Design

PVC boxes can be easily molded into various shapes and sizes, accommodating unique toy designs and branding requirements. They support a range of printing techniques, including silk screen and offset printing, allowing for vibrant and detailed graphics.

4. Cost-Effectiveness

PVC packaging offers a balance between quality and affordability, making it a preferred choice for many businesses. Its lightweight nature reduces shipping costs and makes handling more convenient.

5. Versatility

PVC boxes are suitable for a wide range of toys, from action figures to plush toys. Their adaptability makes them ideal for various product lines within your company.

FAQs of PVC Boxes Custom Printing

1.Q: Can I customize the size and shape of the PVC boxes?

A: Yes, all PVC boxes are fully customizable in size, shape, and structural design.

2.Q: Is your PVC material safe for food or cosmetic packaging?

A: Absolutely. We use non-toxic, food-grade PVC compliant with international standards.

3.Q: What’s the minimum order quantity (MOQ)?

A: The MOQ is usually 1000 pcs, but we offer flexible solutions for trial orders.

4.Q: Can you match the printing colors exactly to my brand colors?

A: Yes, we offer Pantone color matching and sample proofing to ensure accurate branding.

5.Q: How long does production typically take?

A: Normally 7–12 working days after artwork confirmation, depending on quantity.

6.Q: Are these boxes suitable for shipping heavy items?

A: They are best for display and light-medium weight items; for heavy-duty needs, we suggest adding reinforcements or switching to PET/PP.

7.Q: Can you help design the PVC boxes for me?

A: Yes, our in-house design team offers artwork setup, dieline creation, and visual mockups.

8.Q: Will the print fade or peel off over time?

A: No. We use high-quality UV and screen printing that adheres well to PVC and resists fading.

9.Q: Do you offer samples before full production?

A: Yes, both digital mockups and physical pre-production samples are available upon request.

10.Q: Can you ship to my country?

A: Yes, we export worldwide with secure packing and competitive international freight rates.

11. Is full color printing on the plastic packaging boxes OK?

A: Yes,full color printing is avaialble.

12.Is this kind of packaging safe for my food storage?

A: Yes,the materials we used are eco-friendly and food grade which are fit for the food grade standard. You can test the material which are biodegradable.

13. How can I pay? And what is the MOQ?

A: MOQ is 1000pcs per design. You can pay via Paypal,TT,Western Union or Moneygram…etc

Related products

Boxes Packaging printing

Boxes Packaging printing

Tin Case Safety Metal Tinplate Case 3D Logo For Golf Tee Pack

Boxes Packaging printing

Personalized Box Packaging 100% Natural Fiber Biodergradable

Boxes Packaging printing

Boxes Packaging printing

Boxes Packaging printing

Packaging Boxes and Bags Printing

Boxes Packaging printing