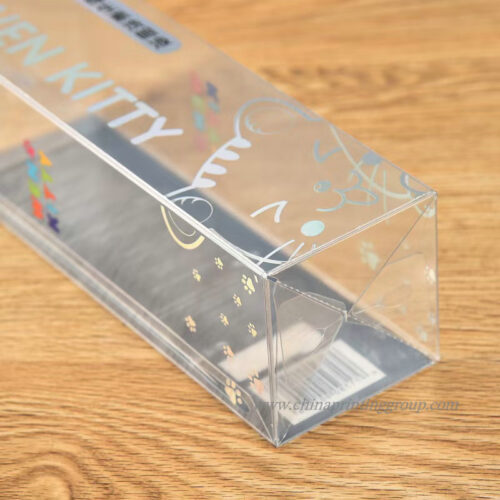

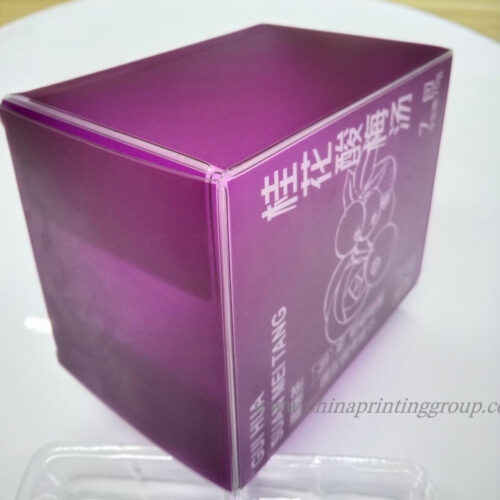

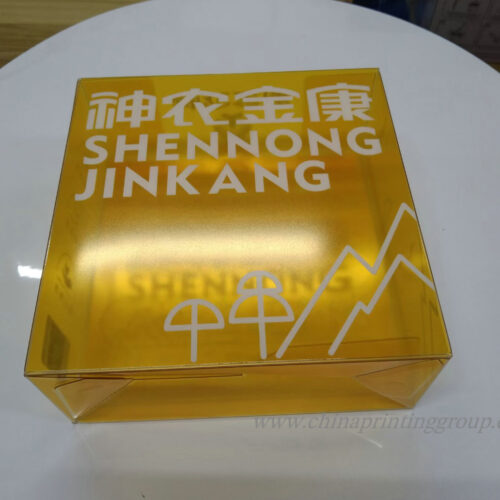

Plastic Packaging Boxes 0.2-1mm Thickness Clear PVC Wholesale Price

Send Inquiry- Use:

-

Juice, Lollipop, Chewing Gum, Noodle, cake, Pizza, Jelly, Sugar, Sandwich, Bread, Snack, OLIVE OIL, Salad, Sushi, Cookie, Seasonings & Condiments, Canned Food, CANDY, Baby Food, PET FOOD, POTATO CHIPS, Hamburger, Nuts & Kernels, Other Food

- Material Structure:

-

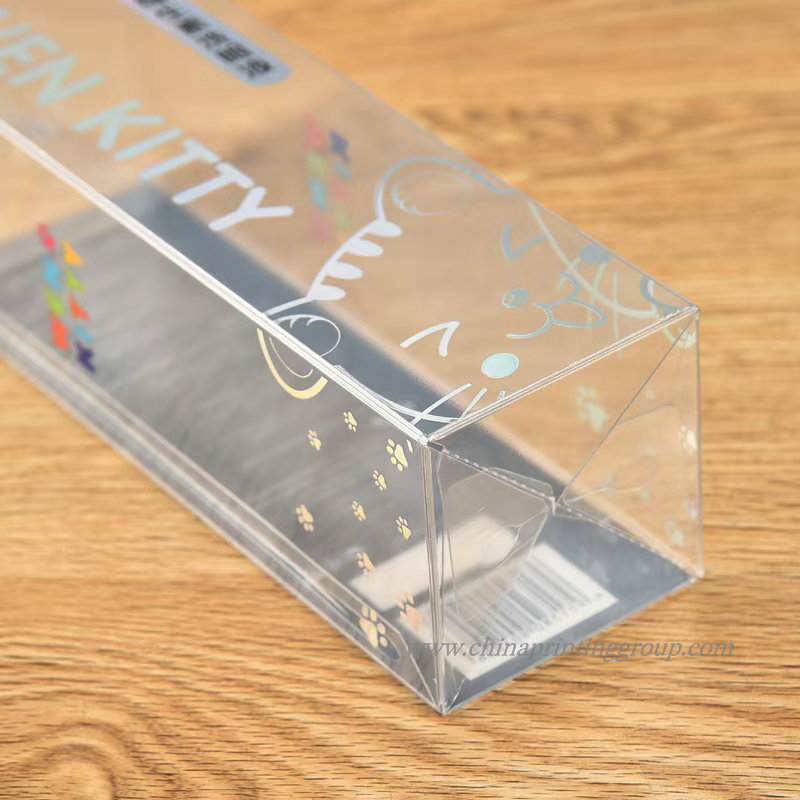

PET PVC Plastic

- Feature:

-

Disposable custom made plastic blister packaging tray

- Material:

-

PVC/PET Plastic

- Thickness:

-

Customized Thickness

- Color:

-

Transparent Clear

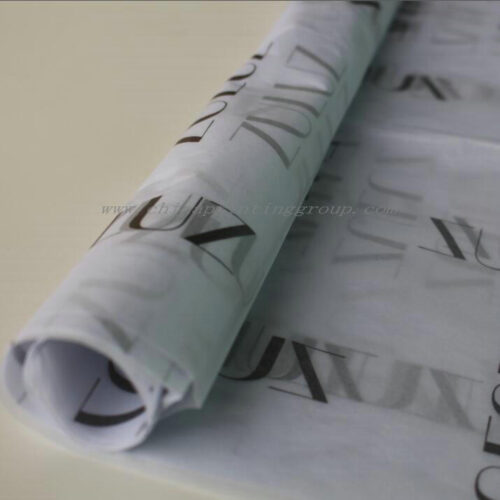

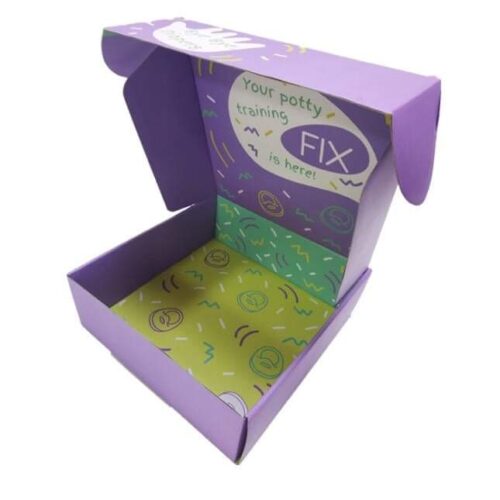

Plastic Packaging Boxes Factory Wholesale Custom Plastic PVC Clear Blister Pack Boxes

- The plastic packaging boxes trays are usually using a sheet material to form a plastic box, with the lid connected to the container.

- Custom made food plastic blister packaging tray with custom design are made with PS material, there are also options for separating the cover and bottom, and different materials can be used.

- For example,we have done some fast food boxes, the bottom is made of black PS and the cover is made of transparent PET.

- The plastic packaging boxes blister packaging: A general term used to produce plastic products using the blister process and to package the products with corresponding equipment.

- Blister packaging products include: transparent plastic tray, bubble shells, trays, blister boxes, and synonyms include: vacuum covers, bubble covers, etc.

Specifications:

|

Product Name

|

Factory Wholesale Custom Plastic PVC Clear Blister Pack Tray Transparent Clear Plastic Tray Boxes |

|||

|

Process Type

|

Blister/Vacuum Forming/Thermoforming

|

|||

|

Material

|

PET/PVC/PS/PP/ABS etc.biodegradable materials

|

|||

|

Color

|

Transparent/Black/White/Customized

|

|||

|

Thickness

|

Customized Thickness

|

|||

|

Size

|

Customized Size

|

|||

|

Shape

|

Customized Shape

|

|||

|

MOQ

|

1000 PCS

|

|||

|

Delivery

|

By air, Express, sea, door-to-door delivery as discussed.

|

|||

|

OEM/ODM

|

Acceptable

|

|||

|

Lead time

|

7-9 working days for bulk production

|

|||

Specifications of Plastic Packaging Boxes:

-

Material:

-

Premium-grade PET, PVC, PP, or eco-friendly biodegradable plastic.

-

-

Dimensions:

-

Fully customizable, ranging from small (5x5x5 cm) to large (60x60x60 cm).

-

-

Thickness:

-

Available thickness from 0.2 mm to 1.0 mm, ensuring durability and protection.

-

-

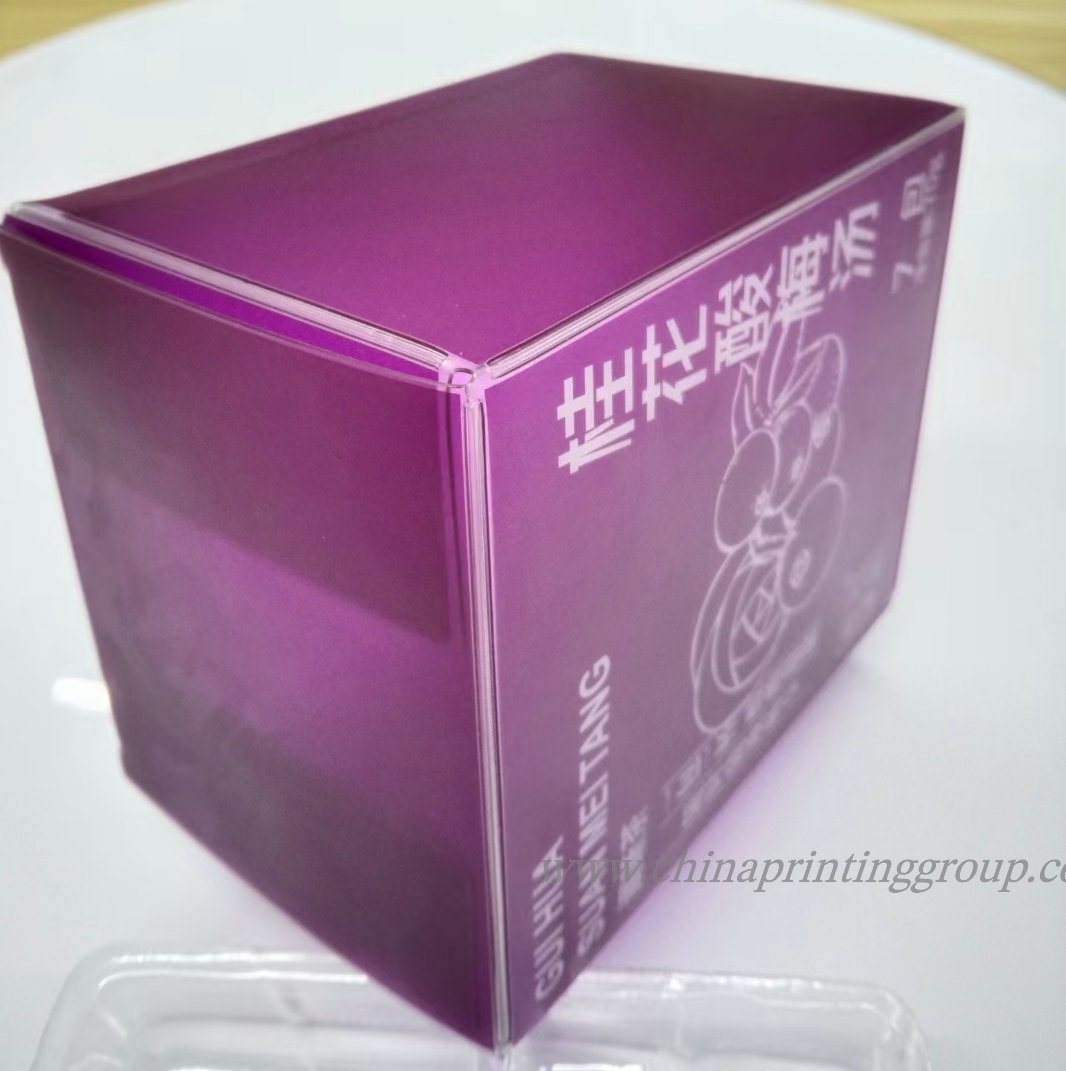

Printing Options:

-

High-quality offset printing, silk-screen printing, UV printing, hot-stamping, embossing, and holographic effects.

-

-

Finishing & Surface Treatments:

-

Glossy, matte, frosted, soft-touch coatings, UV spot varnish, and anti-scratch treatment.

-

-

Closure Types:

-

Auto-lock bottoms, tuck-end closures, magnetic closures, snap closures, or handles for easy carrying.

-

-

Transparency:

-

Crystal clear clarity or tinted options available for showcasing products attractively.

-

-

Safety and Compliance:

-

Food-grade certification, FDA approved, REACH, and RoHS compliant materials available.

-

-

Eco-Friendly Features:

-

Recyclable, reusable, and biodegradable options to support sustainability initiatives.

-

-

Customization:

-

Tailored shapes, windows, die-cut designs, and inserts available to enhance product presentation and protection.

Our Advantages:

-

Quality Assurance:

-

Strict quality control procedures to guarantee superior product consistency and reliability.

-

-

Customization Expertise:

-

Professional in-house design team offering tailored packaging solutions for enhanced brand visibility.

-

-

Eco-Conscious Commitment:

-

Providing environmentally-friendly packaging materials and actively supporting sustainable practices.

-

-

Competitive Pricing:

-

Cost-effective pricing structures achieved through efficient production management and optimized resource utilization.

-

-

Fast Lead Times:

-

Quick turnaround for urgent orders through streamlined production processes.

-

-

Advanced Production Techniques:

-

Cutting-edge machinery and technology ensuring precision, quality, and consistency.

-

-

Customer Service Excellence:

-

Dedicated, responsive customer support team providing personalized service throughout the entire order process.

-

Applications of Plastic Packaging Boxes:

-

Retail and Consumer Goods:

-

Ideal for electronics, stationery, clothing, footwear, accessories, and toys, providing clear visibility to boost consumer appeal.

-

-

Cosmetics and Personal Care:

-

Perfect for packaging perfumes, skincare products, makeup items, and toiletries with elegant aesthetics.

-

-

Food and Confectionery:

-

Food-grade options suitable for chocolates, candies, baked goods, and gourmet snacks.

-

-

Pharmaceutical and Healthcare:

-

Hygienic and protective packaging for medical supplies, OTC products, supplements, and wellness products.

-

-

Gift and Promotional Packaging:

-

Custom-designed boxes to enhance the perceived value of gift items, event giveaways, and promotional products.

-

-

Industrial and Commercial Uses:

-

Robust packaging solutions for precision components, hardware, tools, and spare parts.

-

-

Jewelry and Luxury Goods:

-

Sophisticated packaging providing excellent product visibility, protection, and enhanced brand image.

-

Choose our plastic packaging boxes for exceptional quality, tailored branding, sustainable solutions, and versatile applications tailored precisely to your business needs.

📌 Price Structure of Plastic Packaging Boxes:

Prices for plastic packaging boxes generally depend on the following factors:

| Pricing Factor | Description & Cost Impact |

|---|---|

| Material Choice | PET, PVC, PP, or biodegradable materials vary in cost, with PET and biodegradable options typically higher. |

| Box Size & Dimensions | Larger boxes and custom dimensions incur higher costs due to material consumption and tooling. |

| Material Thickness | Thicker materials (e.g., 0.7 mm–1.0 mm) increase the price due to enhanced durability. |

| Printing Methods | Offset printing, silk-screen, UV printing, hot-stamping, and embossing involve additional costs based on complexity and color count. |

| Surface Treatments | Matte, glossy, frosted, or special treatments (e.g., UV spot varnish, anti-scratch) have incremental costs. |

| Design Complexity | Intricate die-cuts, custom shapes, and specialized closures (magnetic, auto-lock) require additional tooling fees. |

| Quantity Ordered | Volume discounts apply for larger quantities, significantly reducing per-unit costs at higher order quantities. |

| Additional Accessories | Custom inserts, handles, hang tags, and labels increase overall pricing. |

| Packaging & Shipping | Bulk packaging reduces costs, while individually wrapped units or international shipping may add expenses. |

| Order Lead Time | Rush orders typically incur an expedited production fee. |

General Price Range:

-

Standard plastic box (clear PET, simple shape, minimal printing):

$0.10–$0.50 per unit (for orders above 10,000 units) -

Custom-designed plastic box (special shapes, full-color printing, UV coating):

$0.30–$1.50 per unit (medium complexity, orders around 2,000–10,000 units) -

Premium plastic box (high-end designs, magnetic closures, luxury finishes):

$0.90–$3.00 per unit (lower quantities, highly customized orders)

(Note: Prices listed are indicative only and vary based on exact specifications.)

📌 Why Choose Plastic Packaging Boxes Instead of Paper Boxes?

1. Product Visibility:

-

Plastic boxes provide clear, high transparency, enabling customers to see the product clearly, enhancing visual appeal.

2. Durability and Protection:

-

Superior strength, impact resistance, and waterproofing capabilities, making them ideal for protecting delicate items during transportation and handling.

3. Premium Look and Feel:

-

Plastic packaging boxes provide a sleek, modern appearance, elevating perceived product value and helping brands stand out on retail shelves.

4. Customization Flexibility:

-

Easier to mold into unique shapes, offer complex die-cuts, inserts, and precise dimensions compared to paper boxes.

5. Enhanced Branding Options:

-

Plastic packaging boxes surfaces support vibrant printing methods (UV printing, hot-stamping, embossing) better than paper, resulting in sharper, brighter colors and textures.

6. Longer Shelf-Life:

-

Plastic packaging boxes offer superior moisture, dust, and contamination resistance, keeping products fresher and cleaner for longer periods.

7. Reusability and Recyclability:

-

High-quality plastic packaging boxes can be reused multiple times, appealing to eco-conscious consumers, with recyclable and biodegradable options available.

8. Better for High-End & Luxury Products:

-

Premium finishes, clear visibility, and upscale aesthetics make plastic packaging boxes the preferred choice for luxury, cosmetics, electronics, and gift industries.

9. Weather and Environmental Resistance:

-

Plastic packaging boxes provide excellent resistance against humidity, temperature changes, and environmental damage compared to paper-based packaging.

10. Cost-Efficiency Over Time:

-

Although plastic packaging boxes may initially cost slightly more than paper, the added protection, reduced damage, longer shelf-life, and higher consumer appeal often result in better ROI overall.

Choose plastic packaging boxes for enhanced visibility, superior durability, high-end presentation, and versatile customization—significantly strengthening your product’s market positioning.

🎨 Our Designing Services Include:

1. Artwork & Graphic Design

-

Professional graphic designers to create visually appealing artwork aligned with your brand identity.

-

Customized designs for logos, graphics, illustrations, and visual elements to ensure maximum brand impact.

2. Packaging Structural Design

-

Customized structural solutions to precisely fit your product, enhancing protection and visual presentation.

-

Creation of accurate die-lines and 3D mockups to visualize the final packaging clearly.

3. Material & Finish Selection Guidance

-

Expert advice on selecting suitable materials (PET, PVC, PP, biodegradable plastics).

-

Recommendations for optimal finishes (glossy, matte, frosted, UV, hot-stamping, embossing) to enhance appeal.

4. Pre-press & Color Management

-

Accurate color matching (Pantone color matching system) and pre-press management to maintain brand consistency.

-

Professional digital and offset printing techniques for vibrant, high-resolution graphics.

5. Prototyping & Sample Creation

-

Production of physical samples or prototypes before mass production, enabling you to verify design accuracy and quality.

-

Easy adjustments based on your feedback to finalize the perfect packaging design.

6. Branding & Marketing Consulting

-

Strategic recommendations to make your packaging appealing to your target market.

-

Insights and guidance on packaging trends, consumer preferences, and market positioning.

📝 Design Process (Step-by-Step):

-

Step 1: Initial Consultation

-

Discuss your packaging goals, brand identity, and target market.

-

-

Step 2: Concept Development

-

Create initial designs, sketches, and visual concepts based on your brief.

-

-

Step 3: Review & Feedback

-

Review and adjust design drafts based on your input and preferences.

-

-

Step 4: Prototype/Sample Creation

-

Produce a physical sample to ensure satisfaction with materials, colors, and overall design.

-

-

Step 5: Final Approval

-

Confirm the final design, artwork, dimensions, and finishes before production.

-

-

Step 6: Production & Delivery

-

Begin manufacturing your custom-designed plastic packaging boxes with rigorous quality control.

-

⏳ Typical Design Turnaround Time:

-

Initial designs: 2–4 working days

-

Adjustments & revisions: within 1–2 working days per revision

-

Physical prototype/sample: 3–7 working days after design approval

💲 Design Costs:

-

Basic design services (existing brand assets, minor adjustments): Usually complimentary.

-

Comprehensive, full-package design services (logo creation, custom artwork, complex die-line design): Typically range from $50 to $300, depending on complexity.

(Design fees may be waived or discounted for larger orders.)

We aim to make your plastic packaging boxes visually impactful, highly marketable, and perfectly aligned with your branding goals. Let us help you create packaging that stands out.

🌟 How to Create Standout Plastic Packaging Boxes?

1. Unique Structural Design

-

Opt for distinctive shapes or structures that differentiate your product clearly on retail shelves.

2. Eye-catching Graphics & Branding

-

Use vibrant colors, bold graphics, professional artwork, and sharp logos to capture consumer attention quickly.

3. Quality Finishing & Special Effects

-

Consider finishes such as matte, glossy, UV coating, hot stamping, embossing, or holographic effects for a premium feel.

4. Transparency & Visibility

-

Utilize clear windows or fully transparent plastic packaging boxes to showcase the product, enhancing customer trust and appeal.

5. Functional & Convenient Features

-

Add easy-open closures, handles, auto-lock bottoms, or reusability options to enhance consumer convenience.

6. Eco-friendly Materials

-

Select recyclable or biodegradable materials that appeal to environmentally conscious customers, reflecting your brand’s values.

💰 How We Help You Get Cost-effective Packaging Boxes:

-

Bulk Order Discounts

-

Volume-based pricing allows significant savings with higher quantities.

-

-

Material Optimization

-

Expert advice on choosing the right thickness and materials to balance quality and budget effectively.

-

-

Efficient Production Process

-

State-of-the-art manufacturing facilities optimize productivity, reducing costs and ensuring competitive prices.

-

-

Design Efficiency

-

Our experienced design team recommends cost-saving packaging structures, minimizing material wastage.

-

-

Flexible Customization

-

Offering multiple cost-effective customization options (simple yet impactful printing techniques, affordable finishing options).

-

🤝 Why Trust Our Company?

-

Extensive Industry Experience

-

Over a decade of experience in packaging manufacturing and design, serving global brands and businesses.

-

-

Quality Assurance

-

Rigorous quality control processes and certified manufacturing standards (ISO, FDA, RoHS compliance).

-

-

Proven Track Record

-

Positive customer testimonials, repeat business, and high customer satisfaction rates.

-

-

Transparent Communication

-

Clear pricing, no hidden charges, and open communication through every step of your order.

-

-

Sustainability Commitment

-

Dedicated to eco-friendly practices, helping your brand align with sustainability goals.

-

📦 Our After-Sales Services:

-

Quality Guarantee

-

We fully stand behind our product quality. If there’s any defect or discrepancy, we offer replacements or suitable solutions promptly.

-

-

Dedicated Customer Support

-

Responsive support available via email, phone, or messaging platforms, promptly handling your queries or concerns.

-

-

Technical & Design Support

-

Continuous assistance even after delivery, including guidance on optimal storage, usage, and disposal.

-

-

Order Tracking & Updates

-

Real-time updates throughout production and shipping to ensure you stay informed.

-

-

Feedback & Continuous Improvement

-

Regular follow-ups post-delivery to collect your feedback, continuously refining our products and services.

-

Choose us for standout, cost-effective plastic packaging boxes, backed by trustworthy service and comprehensive after-sales support, ensuring your packaging not only attracts attention but also enhances your brand’s reputation and market appeal.

We offer free digital mock-ups for your plastic packaging boxes!

🎯 Our Free Mock-up Service:

-

Digital Mock-up:

Free high-quality digital 3D visualization of your packaging, helping you clearly understand how your final boxes will look. -

Design Preview:

Includes your branding, artwork, dimensions, and finishing details for accurate representation. -

Easy Adjustments:

You can easily request adjustments to dimensions, colors, or artwork until fully satisfied, without additional charges.

📌 Process of Getting Your Free Mock-up:

-

Send Your Requirements:

Share your logo, artwork, product dimensions, and desired box style. -

Design Creation:

Within 2-3 business days, receive your customized digital mock-up. -

Review & Feedback:

Request modifications if necessary; adjustments are usually completed within 24–48 hours. -

Final Approval:

Confirm the mock-up design before moving forward to sample or production.

Note:

-

Physical samples may incur minimal charges depending on complexity and shipping costs, but digital mock-ups remain completely free.

Let’s create your standout packaging—request your free mock-up today!

FAQ:

1. Could you please let me know which products can be used for the plastic blister packaging?

A: This clear plastic packaging are widely used in various fields, such as food packaging, medical packaging, cosmetic packaging, stationary packaging, electronic products packaging, gift packaging, hardware tools packaging…etc. Our blister packaging are biodegradable.

2. Is this kind of plastic packaging boxes printing can be spot UV for my LOGO?

A: Yes,spot UV varnishing on your logo is available.

3. How can I make the order?

A: Once you confirm the quotation which we offered according to your custom design of plastic tray and packaging,we will make a sample for approval before bulk printing,then you pay the deposit for us to proceed with the mass production. All the goods are ready before shipment,you will need to pay the balance.

4. What materials do you use for plastic packaging boxes?

We primarily use PET (Polyethylene Terephthalate), PVC (Polyvinyl Chloride), PP (Polypropylene), and eco-friendly biodegradable plastics. PET is popular for high clarity, PVC for durability, PP for flexibility, and biodegradable plastics for sustainability.

5. Are your plastic packaging boxes food-safe?

Yes. We offer FDA-approved, food-grade plastic packaging boxes specifically designed for safe food contact. These comply fully with international food safety standards.

6. Can I customize the dimensions and shape of the boxes?

Absolutely. All our plastic boxes can be fully customized according to your specific product requirements. We offer tailored dimensions, shapes, die-cuts, inserts, and closures.

7. What printing methods do you offer for plastic packaging boxes?

We provide multiple high-quality printing options, including offset printing, silk-screen printing, UV printing, hot-stamping, embossing, holographic, and spot UV finishes, all enhancing your branding impact.

8. Do you offer environmentally friendly plastic packaging boxes?

Yes. We have eco-friendly solutions such as recyclable plastics, biodegradable materials, and reusable designs, supporting your sustainability initiatives and reducing environmental impact.

9. What is the minimum order quantity (MOQ) for custom plastic packaging boxes?

Typically, our MOQ starts from 500–1,000 units per design, depending on complexity, box size, and customization options. Smaller quantities are available but may result in higher per-unit costs.

10. How long does it take to produce and deliver my plastic packaging boxes?

Standard production lead time is 10–15 days after artwork approval. Expedited production (within 5–7 days) is possible upon request, though additional fees may apply.

11. Can you help me design my platic packaging boxes artwork?

Certainly. Our professional design team offers comprehensive assistance in creating artwork, die-lines, mock-ups, and prototypes, ensuring your packaging aligns perfectly with your branding and marketing goals.

12. Are plastic packaging boxes more expensive than paper boxes?

Initially, plastic packaging can be slightly more expensive than paper packaging. However, they offer superior protection, clarity, durability, moisture resistance, and a premium presentation, often resulting in better value and cost-effectiveness overall.

13. How will my plastic packaging boxes be shipped, and will they be protected?

Boxes are carefully packed in sturdy cartons with inner protective wrapping to ensure they arrive safely and without damage. We provide multiple shipping options, including sea, air, and express courier services.

Related products

Packaging Boxes and Bags Printing

Boxes Packaging printing

Boxes Packaging printing

Tin Case Safety Metal Tinplate Case 3D Logo For Golf Tee Pack

Packaging Boxes and Bags Printing

Boxes Packaging printing

Boxes Packaging printing

Boxes Packaging printing