Clear Sticker Printing Customized Vinyl Self Adhesive Transparent Label

Send Inquiry- Material:

-

Vinyl, PVC, PET, Metal are available

- Use:

-

Coffee, Juice, Mineral Water, Tea, Carbonated Drinks, Other Beverage

- Color:

-

Full colors CMYK, or Pantone Colors

- Shape:

-

Rectangel, Round, Oval, Die cutting

- Ink:

UV ink, Weather Resistant

- Packing:

-

Rolls & Individual Sheets

- Delivery time:

-

3-5 working days after proof approval

Clear Sticker Printing Customized Vinyl Self Adhesive Transparent Label

- Custom transparent vinyl clear sticker printing is currently widely used in various industries across the country, mainly in packaging or products in the food industry, packaging industry, software industry, mechanical equipment and other industries.

- The advantages of transparent vinyl labels custom printing are good moisture resistance, excellent water resistance, good oil resistance, ability to meet high-speed automatic labeling speed, and very beautiful visual effects.

- The raw materials for vinyl transparent labels self adhesive are mainly divided into two types:

1st one is plastic PP transparent material, which is affordable and suitable for application in products with low requirements; Another type is highly transparent PP material, which uses a transparent clear vinyl stickers or self adhesive labels made of fully transparent PET backing paper.

This material has a higher perspective than plastic or PVC transparent adhesive labels with custom Logo printing and is also relatively sturdy, which can resist stretching and tearing well

Specifcation:

| Product Name |

Customized Printing LOGO Self Adhesive Clear Stickers Vinyl Transparent Label or Clear Sticker Printing

|

|||

|

Design

|

AI/CDR/EPS/PDF/JPG,outlined fonts on the file for vector file required. Resolution of the images are more than 300dpi. With 3mm bleeding added on each edges of the design.

|

|||

|

Thickness

|

0.025mm /0.038mm /0.050mm /0.080mm/ 0.100mm Or customized thickness

|

|||

|

Samples

|

Samples of our previous work or samples according to your designs are available

|

|||

|

Finished

|

Sticker on sheet/ Sticker on roll

|

|||

|

Adhesive

|

Standard adhesive on the back /More stronger /3M adhesive

|

|||

Wholesale Transparent PVC/PET Stickers with Logo or Custom Printing Clear Vinyl Labels

- Are you looking for stickers to enhance your branding and packaging? Clear sticker printing has become a popular choice for you. With the advanced printing technologies, clear stickers provide a transparent, no-label look that can make any product stand out.

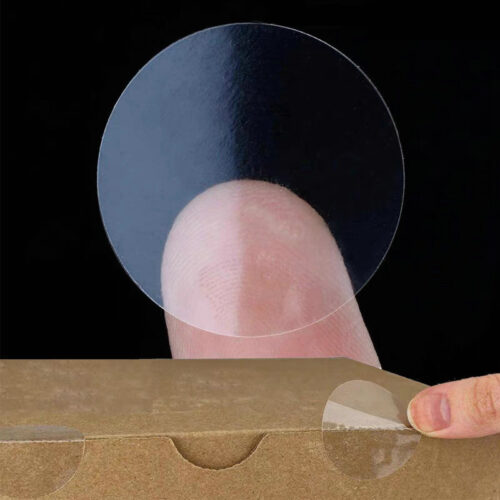

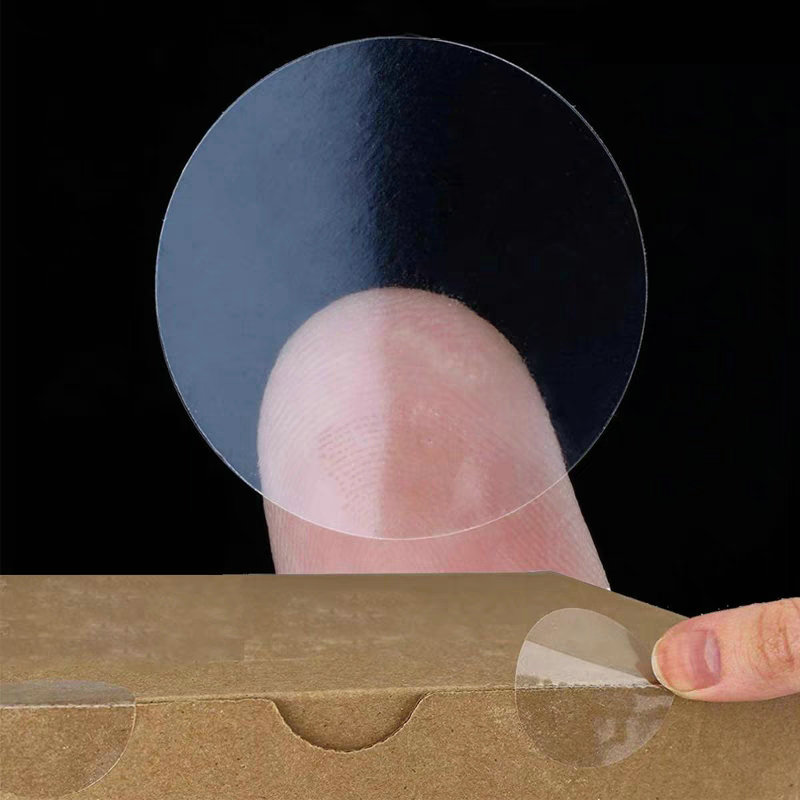

- Clear stickers are typically laminated to protect the print and enhance durability.They are then cut to the desired shape using precision cutting tools

What is Clear Sticker Printing?

Clear stickers are made from high-quality transparent materials such as polypropylene (PP) or vinyl. These stickers are durable, waterproof, and resistant to fading and scratching, available for both indoor and outdoor use.

- Clear Vinyl Stickers: Known for their flexibility and durability, ideal for outdoor applications.

- Clear BOPP Stickers: Commonly used for food and beverage packaging due to their resistance to moisture and oil.

Key Features

Transparency: Provides a clean, seamless look.

Durability: Resistant to water, UV light, and chemicals.

Used in various areas: Suitable for various surfaces including glass, plastic, and metal.

Customizability: Available in multiple shapes, sizes, and finishes.

Why choose Chinaprintinggroup for clear sticker printing?

- Known for fast turnaround times and high-quality prints.

- Offers extensive customization options and excellent customer service.

- Provides durable and weatherproof stickers suitable for various industries.

Factors Affecting Cost:

- Quantity: Bulk orders typically reduce the per-unit cost.

- Size and Shape: Custom sizes and shapes may incur additional charges.

- Material: High-quality materials like vinyl can be more expensive than standard options.

Price Range of Clear Sticker Printing

- Small orders (500 stickers) may start at around $50.

- Larger orders (10,000 stickers) can go up to $500, offering significant savings per unit.

Ordering Process:

- Artwork providing:

Please provide your artwork, which is then reviewed by theour design team.Chinaprintinggroup offers free design proofs to ensure the design is accurate and meets your expectations before moving forward with production.

If you don’t have your design,then our designing team can offer custom illustration graphics services. - Artwork approval before production started:

Once the design is finalized, a digital proof of clear sticker printing is sent to the client for approval.

This proofing stage is crucial as it allows the client to make any necessary adjustments before the printing process begins. We offer high-quality proofs to ensure that the colors, dimensions, and overall design will be printed correctly. - Clear Sticker Printing methods:

Different printing technologies can be employed depending on the project requirements and the volume of stickers needed.1) Digital printing is commonly used for smaller runs and custom orders due to its flexibility and quick turnaround times. This method uses advanced digital printers, like the HP printer, to produce high-resolution prints with vibrant colors.2) For larger orders, screen printing is often preferred. This method involves creating a stencil (or screen) for each color and pressing ink through the screen onto the vinyl material. Screen printing is known for its durability and excellent color saturation.

3) UV printing is used for outdoor using stickers which are waterproof,fade-resistant,anti-UV, weather resistant..etc.The printing ink and materails are more special than regular ones. -

Lamination and Finishing

After printing, the clear stickers are laminated to protect the printed layer from damage and enhance their durability. You can choose between a glossy or matte finish based on their aesthetic preferences and the intended use of the clear sticker printing.

Glossy Finish

A glossy finish adds a shiny, reflective quality to the stickers, making colors appear more vibrant. This type of finish is ideal for products that need to stand out on shelves or for outdoor applications where weather resistance is important.

Matte Finish

A matte finish provides a more subdued, non-reflective look, which can be beneficial for applications where glare needs to be minimized. Matte finishes also offer a premium, sophisticated appearance, often used for high-end product labeling.

-

Cutting and Shaping

Once laminated, the stickers are cut to the specified shapes and sizes. Digital cutting machines are used to achieve precise cuts, allowing for custom shapes that can accommodate intricate designs. This step is crucial for ensuring that the stickers fit perfectly on the intended surfaces.

-

Quality Control and Shipping

Before shipping, the stickers undergo a rigorous quality control process to ensure they meet the specified standards. This includes checking for color accuracy, print quality, and adhesive performance. Only after passing these checks are the stickers packed and shipped to you.

How to make the right decision of clear sticker printing for my products?

- Choosing the Right Material

Different materials offer various benefits, so it’s important to choose the one that best suits your needs.

Clear vinyl is ideal for outdoor use due to its durability and weather resistance.

Clear BOPP is great for food packaging as it is oil and moisture resistant. - Design Elements

Consider how your design will look on a transparent background.

Using white ink behind colors can help make the design pop and ensure it is clearly visible.

Lighter colors tend to stand out better against clear backgrounds. - Application Surface

Clear stickers adhere best to smooth, non-porous surfaces like glass, plastic, and metal.

Ensure the surface is clean and dry before applying the sticker to avoid bubbles and ensure a strong bond.

- By considering key factors like material choice, design elements, and application surfaces, you can ensure that the clear stickers not only look great but also perform well in your intended applications.

- By understanding the types, applications, and manufacturing processes, you can make informed decisions when selecting stickers printing services. Whether for promotional purposes or product labeling, clear stickers provide a durable and attractive option that enhances brand visibility.

- Chinaprintinggroup is the right supplier, based in China,you can have our high-quality printing services to create custom clear stickers that meet your specific needs. From the initial design to the final product, each step in the process is crucial to achieving the desired outcome.

What Is Clear Sticker Printing?

Clear sticker printing refers to printing custom designs onto transparent or semi-transparent adhesive materials, typically made from clear vinyl, PET, or polypropylene (PP). Unlike white or paper stickers, clear stickers allow the surface underneath (glass, plastic, metal, packaging) to remain visible, creating a “no-label” or seamless look.

Clear stickers are widely used in:

-

Product packaging

-

Bottles and jars

-

Cosmetics and skincare

-

Food and beverage labeling

-

Electronics

-

Promotional branding

They are especially popular among brands that want a clean, modern, premium, and minimalist appearance.

Key Advantages of Clear Sticker Printing

1. Premium “No-Label” Look

Clear stickers blend into the product surface, making graphics and text appear printed directly on the packaging, not as a separate label.

Best for:

-

Glass bottles

-

Transparent containers

-

Luxury or minimalist branding

2. Strong Visual Focus on Logo & Design

With no visible background, the logo, typography, and artwork stand out clearly, enhancing brand recognition.

3. Versatile Applications

Clear stickers adhere well to:

-

Glass

-

Plastic (PET, PVC, HDPE)

-

Metal

-

Smooth coated paper boxes

4. Durable & Waterproof Options

Most clear stickers are printed on vinyl or PET, offering:

-

Waterproof protection

-

Oil resistance

-

Scratch resistance

-

UV resistance (for outdoor use)

5. Flexible Printing Effects

Clear sticker printing supports:

-

White ink underprinting

-

Spot white highlights

-

CMYK + white

-

Foil stamping

-

Spot UV varnish

-

Matte or gloss finishes

How to Choose the Best Clear Sticker Printing for Your Products?

Step 1: Identify Your Product Surface

-

Glass or plastic?

-

Transparent or colored?

-

Smooth or textured?

Tip: Dark bottles require white ink for readability.

Step 2: Define Usage Environment

-

Indoor or outdoor?

-

Exposure to water, oil, UV?

-

Refrigeration or freezer use?

Step 3: Choose the Right Material

-

Vinyl → durability

-

PET → premium clarity

-

PP → budget option

Step 4: Decide on White Ink Strategy

-

Full white base for bold colors

-

Partial white for layered effects

-

No white for subtle branding

Step 5: Select Finish & Shape

-

Gloss for eye-catching retail

-

Matte for luxury feel

-

Die-cut for uniqueness

Step 6: Consider Quantity & Budget

-

Digital printing for flexibility

-

Screen printing for volume savings

-

UV printing for premium quality

Common Mistakes to Avoid

❌ Skipping white ink on dark packaging

❌ Using weak adhesive on curved bottles

❌ Choosing paper instead of waterproof material

❌ Low-resolution artwork (must be 300 DPI)

Why Professional Clear Sticker Printing Matters

High-quality clear sticker printing:

-

Enhances brand perception

-

Improves shelf appeal

-

Increases customer trust

-

Reduces peeling, fading, and returns

Your sticker is often the first physical interaction customers have with your brand—quality matters.

Clear sticker printing is not just about transparency—it’s about precision, material choice, ink technology, and finishing details. By selecting the right combination, your products can achieve a premium, seamless, and professional appearance that stands out in competitive markets.

Materials Used in Clear Sticker Printing

1. Clear Vinyl Stickers (Most Popular)

Best all-around option

-

Flexible and durable

-

Waterproof and weather-resistant

-

Ideal for bottles, packaging, and outdoor use

-

Strong adhesive options available

Recommended for:

Cosmetics, beverages, candles, retail packaging

2. Clear PET Stickers

Premium & eco-friendlier

-

Higher transparency than vinyl

-

Excellent dimensional stability

-

More recyclable

-

Less stretching than vinyl

Recommended for:

High-end products, cosmetics, electronics

3. Clear PP Stickers

Cost-effective solution

-

Lightweight and smooth

-

Suitable for indoor use

-

Lower durability than vinyl/PET

Recommended for:

Short-term promotions, indoor packaging

Printing Technologies for Clear Stickers

1. Digital Printing (Small–Medium Runs)

-

Fast turnaround

-

Ideal for customization

-

No plate cost

-

Best for 100–5,000 pcs

Limitations:

Color density may vary without white ink

2. UV Printing

-

Direct ink curing on material

-

High opacity

-

Excellent scratch resistance

-

Supports spot white and spot UV

Best for:

High-quality clear labels with strong color contrast

3. Screen Printing

-

Extremely opaque white ink

-

Best durability

-

Consistent color for large volumes

Best for:

Mass production (10,000+ pcs)

The Importance of White Ink in Clear Sticker Printing

Why White Ink Matters

Without white ink, colors printed on clear material will appear:

-

Semi-transparent

-

Washed out

-

Strongly affected by the background color

White Ink Options

-

Full White Base – solid colors, strong contrast

-

Partial White Ink – only under logos/text

-

No White Ink – minimalist transparent effect

Professional brands almost always use white ink for logos and text.

Adhesive Options for Clear Stickers

1. Permanent Adhesive

-

Strong bonding

-

Not removable

-

Best for retail products

2. Removable Adhesive

-

Clean removal

-

No residue

-

Ideal for promotions or temporary use

3. Freezer-Grade Adhesive

-

Works in cold and moist environments

-

Suitable for frozen food packaging

Finishing Options to Enhance Your Clear Sticker Printing

| Finish Type | Effect | Best Use |

|---|---|---|

| Gloss Lamination | Shiny, vibrant | Beverage, cosmetics |

| Matte Lamination | Soft, premium | Luxury branding |

| Spot UV | Raised glossy areas | Logos, highlights |

| Foil Stamping | Metallic effect | Premium packaging |

| Die-Cut | Custom shapes | Unique brand identity |

Artwork Setup Guide for Clear Sticker Printing

1. File Format Requirements

To ensure the best print quality, please provide artwork in vector or high-resolution formats.

Preferred formats

-

AI (Adobe Illustrator)

-

PDF (Print-ready, vector)

-

EPS

Accepted raster formats (if vector is not available)

-

PSD, TIFF, JPG (minimum 300 DPI at final size)

❌ Word, PowerPoint, or low-resolution web images are not recommended.

2. Color Mode & Profiles

-

Color Mode: CMYK

-

RGB files must be converted to CMYK before submission

-

Avoid using screen colors as reference (screen ≠ print)

Tip: Colors on clear material will appear lighter than on white paper.

3. White Ink Setup (CRITICAL for Clear Stickers)

Clear sticker printing requires separate white ink layers to ensure visibility.

3.1 When White Ink Is Needed

-

Logos and text on dark or colored packaging

-

Solid colors that must stay vibrant

-

Small text that needs strong contrast

3.2 White Ink Layer Setup

Create a separate spot color layer for white ink on clear sticker printing.

Standard naming options (confirm with printer):

-

White -

White Ink -

Spot White

Setup rules

-

White ink must be 100% spot color

-

Set to Overprint

-

Do NOT convert white ink to CMYK

3.3 White Ink Coverage Options

-

Full White Base

White under entire design → strongest colors -

Partial White Ink

White only under logo/text → layered transparent effect -

No White Ink

Fully transparent look (best on light surfaces)

4. Bleed, Trim & Safe Area

4.1 Bleed

-

Add 2–3 mm bleed on all sides

-

Extend background or white ink into bleed

4.2 Safe Area

-

Keep text/logos 2–3 mm inside the trim line

-

Avoid placing critical elements near edges

4.3 Die-Cut Line Setup

-

Create die-cut line as spot color

-

Name it:

Die CutorCutContour -

Set to 0.25 pt stroke

-

Set to Overprint

-

Place on a separate top layer

5. Text & Font Guidelines

-

Convert all text to outlines/curves

-

Minimum text size:

-

Positive text: ≥ 6 pt

-

Reversed text: ≥ 7 pt

-

-

Avoid very thin fonts without white ink support

6. Line Thickness & Detail Control

-

Minimum line thickness:

-

CMYK lines: ≥ 0.25 pt

-

White ink lines: ≥ 0.4 pt

-

-

Fine details may disappear without white underprint

7. Transparency & Effects

Allowed

✔ Gradients

✔ Drop shadows (flattened)

✔ Spot UV (on request)

Avoid

❌ Live transparency effects

❌ Multiply/Overlay blending modes

❌ Unflattened effects in final PDF

Always flatten artwork before export.

8. Resolution & Image Quality

-

Raster images: 300 DPI minimum

-

No upscaled web images

-

Avoid excessive compression

9. Finishing Layer Setup (Optional)

If your clear sticker printing includes special effects:

Spot UV

-

Create separate spot color layer named

Spot UV -

100% black spot color

-

Overprint enabled

Foil Stamping

-

Separate spot color layer

-

Name:

Foil/Gold Foil/Silver Foil -

Vector artwork only

10. Background Awareness (Important)

Clear sticker printing are affected by the surface color.

Example:

-

Printed on dark bottle → colors appear darker

-

Printed on transparent bottle → colors appear lighter

Best practice:

Request a digital proof or physical sample before mass production.

11. Final Pre-Submission Checklist

✔ CMYK color mode

✔ White ink layer correctly named

✔ Die-cut line on separate layer

✔ 2–3 mm bleed added

✔ Fonts outlined

✔ Artwork flattened

✔ 300 DPI images

✔ Correct final size

12. Common Artwork Mistakes of Clear Sticker Printing to Avoid

❌ Forgetting white ink layer

❌ Using RGB colors

❌ No bleed

❌ Thin white text without underprint

❌ Not outlining fonts

❌ Expecting screen color accuracy

FAQ:

1.Please Quote:

Transparent and read from the inside of the vehicle.

Need to backing larger than label for easy peel.

Toyota – Window Accident Labels, 20mm x 106mm,

Printed in 4 colours process on 1 side with White base coat.

Clear vinyl sticker, Trim to size

Qty : 1000

Lexus Window Accident Labels, 20mm x 106mm,

Printed in 4 colours process on 1 side. with White base coat.

Clear vinyl sticker, Trim to size

Qty: 500

- Toyota – Window Accident Labels, 20mm x 106mm,

Printed in 4 colours process on 1 side with White base coat.

Clear vinyl sticker, Trim to size

Qty : 1000–USD$115 excluding shipping.

Lexus Window Accident Labels, 20mm x 106mm,

Printed in 4 colours process on 1 side. with White base coat.

Clear vinyl sticker, Trim to size

Qty: 500–USD$105 excluding shipping.

Shipping cost of all the stickers by express to Australia together: USD$55 in total.

2. What surfaces can clear sticker printing adhere to?

- Clear stickers can adhere to a variety of surfaces including glass, plastic, metal, and more.

3. Are clear stickers weatherproof?

- Yes, most clear stickers are weatherproof and UV-resistant, making them suitable for outdoor use.

4. Can I get a proof before printing?

- Yes, Chinaprintinggroup offer free design proofs to ensure your stickers are printed to your specifications.

5. How long does it take to receive my order?

- Standard turnaround times range from 3 to 5 business days, with options for expedited shipping.

6. Are there eco-friendly options of clear sticker printing?

- We can offer recyclable materials for clear stickers, if you have the requirement of environmental sustainability.

7. What is the minimum order quantity of clear sticker printing?

- Minimum order quantities can vary, but we usually offer orders starting from as low as 100 pieces.

8. How do I ensure my colors will print accurately?

- Ensure your design file is in CMYK color mode and has a minimum resolution of 300 dpi.

9. Can clear stickers be removed without leaving residue?

- Yes, high-quality clear stickers are designed to be removed cleanly without leaving adhesive residue.

10. What finishes are available for clear sticker printing?

- Common finishes include glossy and matte laminates, each offering different aesthetic and protective properties.

11. Can clear stickers be used for product labeling?

- Absolutely, clear sticker printing are ideal for product labeling as they enhance the appearance without covering the product itself.Clear sticker printing offers a satisfied solution for various branding and packaging needs.